Whenever I tell anyone I am a sock designer I get an odd look- “a sock designer?! What do you have to do?”

If only you knew how much goes into a sock you would see everyday is different – it’s a great product to design as you have so many options and more often than not a hidden item when worn; you can be as fun and daring as you like!

8:30 am – Arriving at the office I check my emails, usually a couple of questions from the factories about samples being put into work which can usually, be quickly resolved (always priorty as with the time difference in China and Turkey their day is ahead of ours so its imperative I resolve those issues first as not to lose another day). There is then usually a few emails of requests for new designs from my customers so I read through their brief and start to think about what I am going to design.

8:30 am – Arriving at the office I check my emails, usually a couple of questions from the factories about samples being put into work which can usually, be quickly resolved (always priorty as with the time difference in China and Turkey their day is ahead of ours so its imperative I resolve those issues first as not to lose another day). There is then usually a few emails of requests for new designs from my customers so I read through their brief and start to think about what I am going to design.

9:00 am – I check my diary and work plan for the day and prioritise my workload – I catch up with the team in the office on any issues that need resolving internally and of course grab a cuppa to set me up ready for designing!

9:00 am – I check my diary and work plan for the day and prioritise my workload – I catch up with the team in the office on any issues that need resolving internally and of course grab a cuppa to set me up ready for designing!

10:00am – I then set to on new designs… Using Adobe Illustrator I start drawing up patterns, characters and motifs based on either the brief and inspiration the customer has given me or working on a move on to a previous best seller. I look at the trends as I am designing for further inspiration and ensure the colour palettes that I am using are inline with the seasons predictions. Each design; depending on the requests can take time – drawing the characters or motifs could be a couple of hours and then pulling a pack together making sure the colours sit well across a pack needs consideration. Every designer works at a different speed some may be quick others maybe slower but ultimately each designer has a different ‘handwriting’ style and their approach to designing can be free and bold others may be more detailed and complex. It is important as a designer that you understand the end consumer that you are designing for and what that retailer or customer is looking for in their range.

11am – Usually our delivery men arrive with parcels from the factories so there’s excitement through the design area as new samples come in and your cad finally comes to life (however long I have being designing this excitement is the same as the 1st time I ever received a parcel with my samples in!) Samples are reviewed, colours and design checked against the requests, tagged up and popped in the post for the customers selection meetings/approvals.

11am – Usually our delivery men arrive with parcels from the factories so there’s excitement through the design area as new samples come in and your cad finally comes to life (however long I have being designing this excitement is the same as the 1st time I ever received a parcel with my samples in!) Samples are reviewed, colours and design checked against the requests, tagged up and popped in the post for the customers selection meetings/approvals.

12:15pm – It’s lunch time and a walk around the lake near our office it allows time for some fresh air and to relax the mind – be inspired. Followed by a bite to eat on my return to the office.

13:00pm – An internal meeting to discuss styles selected for ordering so the samples are reviewed with the sales, technical and merchandise teams to ensure the product we have designed and created is fit for purpose, that the fit is correct and the design isn’t limiting the amount of stretch in the sock. We consider packaging and how it will be displayed in store and confirm the styles are approved by the customer.

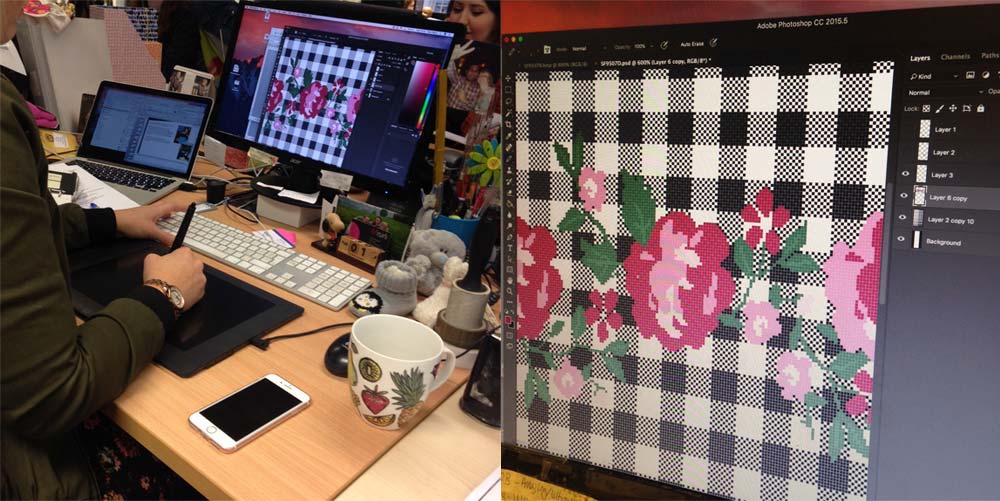

13:30 pm – A customer has emailed me requesting a couple of packs to be sampled so the artwork files need creating in stitch format for the knitting machines – this is called a bitmap. Each square becomes a knitted stitch. Bitmaps are complex and detailed so it takes me time to do these. There is a technical requirement to understand number of needles on the machine to make the sock – how many courses the sock will be and limitations to colours. I consider all of this when creating a bitmap and ensure that the loops (from one colour change to another) are limited as best possible. I then check with our technical product developer who looks a the bitmap with a more mechanical eye and approves it is ok to be sent to the factory for knitting.

15:00 pm – It’s time for another cuppa and to give my eyes a rest from the complexity of the bitmap!

15:00 pm – It’s time for another cuppa and to give my eyes a rest from the complexity of the bitmap!

15:30 pm – I need to select the yarn colours I wish to use on the new samples requested so I revert to the shade books (cottons and nylons) and select the colours. These are listed on the cad as colour chips and labelled which areas they are to knit. A request form is completed and all information is sent to the factory via email for sampling.

16:30 pm – I check my emails again and answer any further questions. I send my design packs over to the customer for their feedback – no doubt when I arrive in the morning they will have emailed with a few tweaks and alterations.

16:45 pm – My customer has approved some samples for production and the orders have been received – I then inform the factory that the samples submitted are approved for colour and design and that yarns can be ordered. I set up a style file and insert the approved samples with the paper work (cad, colours chosen, size spec etc) into a file and store it in the filing cabinets. This pack is there for anyone to access and understand what stage that style is up to in the system.

17:10 pm – It’s time to pack up and leave the office! On the drive home I usually reflect on the day – is there anything I could have done better, any new ideas and think about the following day ahead.

17:10 pm – It’s time to pack up and leave the office! On the drive home I usually reflect on the day – is there anything I could have done better, any new ideas and think about the following day ahead.

The fun thing about being a designer is everyday is different from comp shopping, customer meetings, designing at the office, following up approvals, factory visits, trend research. It is fast paced and demanding which makes it a fun job to have! Another day I will write about visiting factories and comp shopping to give you another “day in the life of a designer”